We pay our respects to their Elders past, present and emerging and celebrate the diversity of Aboriginal peoples and their ongoing cultures and connections to the lands and waters of Queensland.

About the BESS

The Miriam Vale BESS and Solar Farm Development Applications (DAs) were lodged with Gladstone Regional Council (GRC) in mid-2024. You can find more information about the development plans we submitted for the BESS on our Project documents page and for the Solar Farm on our Miriam Vale Solar Farm website.

As a result of listening to community feedback, we have changed the scale and design of the projects significantly since the DAs were lodged. Based on these changes, and the new Planning (Social Impact and Community Benefit) and Other Legislation Amendment Bill 2025, these DAs are likely no longer relevant. PEP therefore withdrew the DAs on Friday, 13 June, and is finalising updated planning and design, and assessing resubmission via the appropriate approval authority.

The below questions and answers provide more information about the BESS and Miriam Vale Solar Farm and are being continually updated as project planning and design evolves.

Battery Energy Storage Systems (BESSs) play a crucial role in supporting Queensland’s energy reliability and stability. They store excess energy from generation sources, or the grid, and release it back into the electricity network when it is needed. This helps reduce electricity waste, maintains continuation of power supply — particularly during periods of lower generation or high demand — and supplies backup power during network disruptions.

The Miriam Vale BESS nameplate capacity is up to 500 megawatts (MW), with up to 8 hours of energy storage.

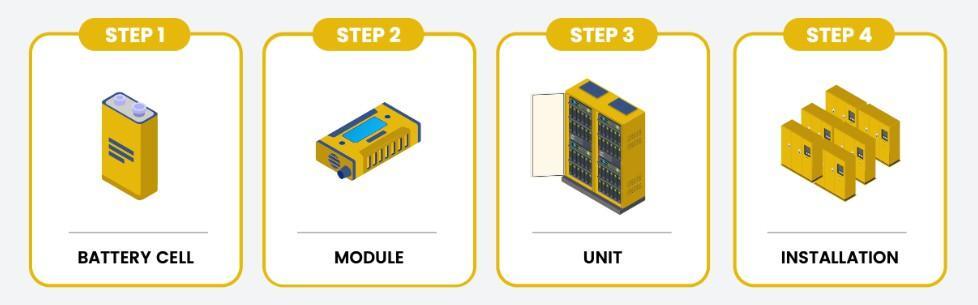

BESS components and systems include:

- Batteries – individual low-voltage, rechargeable battery cells that store energy. These are arranged in racks within a battery module, and modules are grouped together to form a battery unit.

- Battery containers – similar to shipping containers, these heavy-duty steel boxes each house several battery units. Containers are spaced about 3m apart from each other and feature a range of in-built fire suppression and containment systems. The Miriam Vale BESS will include about 120 of these containers.

- Battery Management System (BMS) – monitors and manages the battery’s safety to prevent overcharging, over-discharging and overheating. It also balances the charge across battery cells to maintain optimal performance and longevity.

- Power Conversion System – converts the direct current (DC) from the batteries to alternate current (AC) for use in the grid.

- Thermal Management System – ensures the battery temperature is maintained within a safe operating range.

- Energy Management System (EMS) – controls energy charge and discharge into the grid, using real- time data from the National Energy Market to align electricity storage and release with consumer demand patterns

The Miriam Vale BESS will use grid-scale, Lithium Iron Phosphate (LFP) batteries, which are one of the safest options for large-scale energy storage. These batteries operate across a wider temperature range and store more energy per unit than other types of batteries. This makes them ideal for storing large amounts of electricity for quick release when the power network needs it.

BESS technology is safely and widely used across the world. The system will include advanced monitoring, fire suppression and containment measures to prevent fire risks, and emergency response plans will be in place to manage incidents if they occur.

To protect our communities and keep our team and first responders safe, we engaged Halliwell Fire Research to conduct a detailed fire hazard and dispersion modelling study to analyse the potential consequences of a worst-case fire scenario. This involved simulation of a full-scale BESS unit fire, based on the proposed layout of the site, the specific equipment to be installed, the surrounding land topography and typical local weather conditions. The modelling considered fume and gas dispersion during fire events, fire combustion products and their spread, radiant heat transfer and fire spread risks. The study concluded it was highly unlikely any fault or fire would be significant enough to cause the need for evacuation of neighbours or large exclusion zones.

The modelling showed released gases remained localised, with the majority dissipating to safe levels within 50m of a fire, under moderate wind conditions. The exception was carbon monoxide, which could extend up to 250m downwind. With the closest BESS neighbour residence located about 1km away, this data confirms a BESS fire would not pose a risk to nearby residents or road users. The study used laboratory test results from the battery supplier, which showed fire spreading between BESS containers was highly unlikely in the planned site layout due to internal advanced fire suppression and containment systems, and the spacing between battery containers. Study data will be shared with emergency services and incorporated into emergency response plans to keep people safe in the unlikely event of an incident.

The Miriam Vale BESS has comprehensive safety control systems to keep its neighbours, the community and assets safe. These include:

- systems for the early detection of faults and to contain and suppress fire in each container

- appropriate setbacks and firebreaks to create a buffer between the site boundaries

- emergency response plans and communication protocols to respond in the unlikely event of an incident

BESS equipment will be regularly inspected, tested and serviced according to the manufacturer’s requirements and industry best practice. A sophisticated Battery Monitoring System (BMS) will monitor the system for electrical shorts, faults, equipment failures and temperature increases above defined operating parameters. If issues are detected, the BMS can disconnect and isolate a battery and notify the operator and emergency services.

Laboratory testing showed a fire in a BESS container is highly unlikely to spread or ignite nearby containers, which are made of non-combustible steel that retains its integrity at high temperature, providing a physical barrier to fire spread. The containers feature exhaust ventilation and automatic venting hatches to prevent overpressure damage and ignition of combustible gases. Sprinkler systems are also installed to cool the areas opposite battery packs and the containers’ internal walls, preventing fire spread and helping protect personnel and first responders.

An Uninterrupted Power Supply source will also be installed to ensure all monitoring and safety systems continue to operate in the case of an incident.

Systems and measures to detect, suppress and contain fire will be installed at the Miriam Vale BESS site and commissioned at the earliest possible stage of construction. This will include water tanks, fire hydrants and hoses located across the site in accordance with expert advice and guidelines.

The layout features physical separation between the site and surrounding bush, including fire breaks around

the BESS. The battery storage containers will be easily accessible to emergency services and safely separated from other containers, buildings and car parking. The site will incorporate multiple defined access points around the perimeter for firefighting and QFD will be given a key to the property for 24/7 access in case of emergency.

Should a significant fire occur, any water runoff will be contained and treated to negate potential public or environmental risk.

BESS components, such as battery cooling fans, inverters and transformers, can intermittently emit a tonal humming sound. The BESS noise assessment confirmed day- and night-time operations are within the acceptable noise criteria set out under the Queensland Environmental Protection (Noise) Policy. The BESS noise assessment is available at www.miriamvalebess.com.au/project-documents.

Batteries and inverters produce heat during operation, however, the BESS will have features to ensure safe and efficient equipment performance, including cooling and ventilation systems to keep temperatures within a safe operating range.

General project information

The Project is north of Burgess Road, in Colosseum, about 6km by road from the Miriam Vale town centre and 60km south-west of Gladstone.

This site meets key criteria for successful and responsible renewable energy developments.

These include:

- Existing access to the electricity network – Powerlink Queensland’s high voltage lines already cross the proposed site, eliminating the need for additional transmission easements and allowing energy to be stored from the Solar Farm as well as the electricity network.

- Suitable land characteristics – the topography and size of the site suit a Solar Farm and BESS.

- Low impact on biodiversity – the site was previously cleared for a plantation forestry meaning minimal impact on native vegetation. The Project layout will retain riparian corridors and existing visual screening vegetation.

- Interface with surrounding properties – the site has a limited number of adjoining neighbours, and visual impacts from the surrounding road network can be mitigated.

- Return to existing state after Project – the Project will not alter the agricultural land classification and may allow for grazing on the site during operations as part of weed and vegetation management. The land can also be returned to the prior agricultural use of cattle grazing after Project decommissioning.

PEP has agreed to purchase the land from the existing landholders should the Project be approved and reach the construction phase.

The Project area is about 1000 hectares. This includes the Solar Farm and BESS.

The Project can deliver many short and long-term benefits for Miriam Vale, the surrounding townships and the Gladstone Region.

- The Project will boost the regional economy by employing local people and procuring goods and services from local businesses and contractors, where possible, during construction, operation and decommissioning.

- Employees operating the commissioned Miriam Vale Solar Farm and BESS will reside locally, wherever possible, with no plans for a fly-in, fly-out workforce. This will contribute to the economic growth of local and regional areas.

- PEP will collaborate with residents to establish a Community Partnership Program that provides ongoing benefits to the local community. We welcome and encourage any suggestions from the community as we develop this program. For further information, visit www.miriamvalesolarfarm.com.au/community.

- The supply of renewable energy to the National Electricity Market (NEM) will assist in meeting the Gladstone Region’s demand for increased electricity capacity.

- The Project will help to decarbonise the Queensland electricity grid, put downward pressure on power pricing and support energy reliability.

PEP is committed to employing local people and engaging local businesses, contractors and service providers. This commitment will be passed onto our contractors

Example work packages may include:

● Tree planting for visual screening

● Fencing supply and installation

● Flatbed trailer hire/purchase

● Commercial cleaning

● Bus hire

● Crane and lifting equipment hire and operations

● Water carting

● Concrete work and supply

● Inverter platform supply and installation

● Land management – slashing, weed spraying, pest control

● Solar Farm Balance of Plant – electrical contractors

● Operation and maintenance building

● Site security and systems

● Catering

● Waste management

The Gladstone Engineering Alliance has established a portal for local business and employment opportunities. To register, visit www.gcsp.gea.asn.au. More information will be made available closer to the start of the tender period.

Construction will take about 18 to 24 months. PEP is committed to minimising construction impacts wherever possible and will comply with the construction days and times Gladstone Regional Council (GRC) specifies in the approval conditions.

The expected lifespan of the Miriam Vale Solar Farm and BESS is around 30 years.

Solar farms and BESS projects are designed with strict safety measures, and insurers typically assess risk based on actual hazards, which remain low at this site. The Queensland Renewable Energy Council is working with key agricultural peak bodies and the Insurance Council of Australia to ensure neighbours to renewable energy developments are not subject to increased insurance premiums or exclusions because of the adjacent development. There is currently no evidence that links increasing insurance premiums for neighbours near solar farm or BESS facilities.

PEP is committed to working with the local community to keep them informed and address their concerns. The community can provide feedback at all stages of the Project, with PEP continuing to hold community forums and local information drop-in sessions. You can also contact PEP and the Project team directly at info@miriamvalesolarfarm.com.au or info@miriamvalebess.com.au or by phoning 1800 975 039.

Site planning and considerations

NOISE

The potential impacts and proposed ongoing management of noise have been assessed against the Queensland Environmental Protection (Noise) Policy 2019. To assess potential noise impacts, PEP’s technical specialists monitored ambient noise external to the Project boundary and then modelled predicted noise levels during operations. The results confirmed the completed Project will be compliant with the required noise limits.

During construction, noise impacts will be limited to Council-approved work hours. It is an offence, unless otherwise permitted by Council, to carry out building work that causes an audible noise outside of approved hours. Ongoing noise monitoring will occur at all stages of the Project. Noise generated from the actual equipment, once purchased and tested, will be checked against the modelling. In the unlikely event sound levels are recorded above the required limits, PEP will introduce mitigation measures to reduce the noise to ensure compliance.

The Queensland Environmental Protection (Noise) Policy 2019 is limited to assessing the potential impact to humans. PEP is not aware of any current Queensland guidance that suggests solar farms and BESS developments produce noise that negatively affects wildlife. The Project’s noise assessments are available on the GRC Development Applications website www.gladstone.qld.gov.au/development-application-tracking and on the Project websites www.miriamvalesolarfarm.com. au/project-documents and www.miriamvalebess.com.au/project-documents

LANDSCAPE AND VISUAL AMENITY

A Landscape and Visual Impact Assessment (LVIA) was completed using national best-practice methodologies. This assessment was then updated in response to a Request for Information from GRC during the Development Approval assessment process.

The LVIA sets out actions to mitigate, as far as practical, the visual impacts of the Project. PEP will retain large sections of boundary vegetation and will plant native species during construction for additional screening. Existing and new vegetation will be selected in conjunction with recommendations in the Bushfire Management Plan and will be protected by adequate firebreaks. The LVIA is available on the GRC Development Applications website www.gladstone.qld.gov.au/development- application-tracking and on the Solar Farm website www.miriamvalesolarfarm.com.au/project-documents.

PEP is committed to minimising impact on residents wherever possible and is working with landholders to

understand potential views of the proposed Miriam Vale Solar Farm or BESS.

Vegetation will be used to screen the infrastructure from adjoining roads, however, this will not completely remove all visual impacts. In some instances, partial distant views of the infrastructure from nearby residences may occur (like a distant water body or lake), while in others the infrastructure may present as a filtered image through foliage. PV solar panels are designed to have low levels of reflectivity, enabling maximum light absorption and minimal glint and glare.

TRAFFIC

A Traffic Impact Analysis (TIA) has been completed and will be updated and reviewed as design, construction and workforce planning are finalised. Access to the Project sites will be via the Bruce Highway, Blackmans Gap Road and Burgess Road. Cawthrays Road will only be used in an emergency and Mossman Road is not to be used by Project traffic. No onsite workers’ camp is proposed for the Project.

Intersection analyses, undertaken along the planned routes to site, determined the Blackmans Gap Road intersection will continue to operate satisfactorily during and after construction. PEP will continue to work with GRC and the community to identify, understand and mitigate any further impacts.

The Project’s peak traffic activity will be during construction when materials are trucked to site from the Port of Gladstone via the Bruce Highway. Local construction staff will also use the roads. The largest traffic movements will be the delivery of two 172 tonne off-main power transformers on low-loaders. These ‘oversized and overmass’ deliveries will be managed by pilot and police vehicles. Other than these two units, it is expected that most of the equipment will be delivered to site via truck. The TIA is available on the GRC Development Applications website www. gladstone.qld.gov.au/development- application-tracking and on the Project websites www.miriamvalesolarfarm.com.au/project-documents and www.miriamvalebess.com.au/project-documents.

The TIA indicated only limited upgrade works were needed to facilitate equipment delivery and vehicle movements such as turning circles. However, following feedback from the community, PEP will seek council approval to upgrade Burgess Road to the proposed Project entry to a gravel road before construction starts.

PEP will also submit a Road Use Management Plan, which will include:

● A pre-construction dilapidation report by a Registered Professional Engineer of Queensland (RPEQ) for

Blackmans Gap Road and Burgess Road and associated intersections.

● A construction program with road usage estimates.

● Quarterly RPEQ road inspections during construction, addressing any damage and maintenance

requirements.

● Additional inspections during wet weather.

● safety management protocols, including regular toolbox talks about traffic management and road safety, TMR and GRC-approved traffic management plans, and fatigue management guidelines.

PEP will conduct a post-construction dilapidation assessment and restore roads to pre-construction standards. Existing road reserves on the Project site will be retained.

WATER

PEP is committed to designing the site and construction activities to minimise the use of water and has factored in water scarcity across the broader Miriam Vale region as part of the Council planning process. Most water usage will be for dust suppression during construction, with minimal water used during operations. Following community consultation, PEP can confirm it will not use the existing groundwater bores located on site for construction purposes, wherever possible.

FEDERAL ENVIRONMENTAL APPROVAL:

The Department of Climate Change, Energy, the Environment and Water (DCCEEW) has referred the Project for assessment in accordance with the requirements of the Environment Protection and Biodiversity Conservation Act 1999 (EPBC).

PEP is currently preparing the required documentation to respond to the Department’s request. This includes an assessment of any potential impacts on Matters of National Environmental Significance, such as threatened species, heritage sites, and migratory birds. All necessary approvals will be obtained to ensure compliance with federal regulations. Details of the EPBC process are available online at www.dcceew.gov.au/environment/epbc. Details of the Application are available online at https://epbcpublicportal.environment.gov.au/ (Referral/ Application Ref – 2024/09824).

CULTURAL HERITAGE:

PEP is committed to working with the RNTBC (PBC) to develop a long-term collaborative and beneficial relationship. PEP has commenced engaging with the First Nations Bailai, Gurang, Gooreng Gooreng, Taribelang Bunda People RNTBC (PBC) and will seek to negotiate a Cultural Heritage Management Agreement for the Project.

PEP, in consultation with the RNTBC (PBC) and Port Curtis Coral Coast (PCCC) Trust, has conducted a cultural heritage site inspection and prepared an archaeological report that assessed the Project areas for potential Aboriginal cultural heritage. The report included desktop historical research and a site inspection to establish past land uses and the risk of the development impacting Aboriginal cultural heritage, principally archaeology.

Management Plans

ONGOING SITE MANAGEMENT OF THE SOLAR FARM AND BESS

The Project will have a team dedicated to the maintenance and operation of the site.

- Mechanical and electrical infrastructure inspections and tests will be undertaken regularly, including testing safety and emergency systems and processes.

- Weeds, vegetation, firebreaks, and setbacks will be actively managed under a Weed and Pest Management Plan and in collaboration with neighbours.

- Solar panel cleaning will mostly occur naturally during rainfall events. When additional cleaning is needed, water and a soft brush will be used rather than harsh or hazardous chemicals. Because solar panels and other Solar Farm equipment are manufactured to prevent chemical release when washed (similar to housing materials), these environmentally friendly cleaning processes will not contaminate soil or groundwater.

- Sediment control measures will prevent any stockpiled materials from washing away during heavy rains.

NATIVE WILDLIFE AND FARM LIVESTOCK

PEP is committed to responsibly developing the Project and minimising potential impacts to native wildlife during construction and operations. This includes the following:

- Site evaluation has included ecological investigations and relevant government agencies will assess any potential impacts of the proposed minimal vegetation clearing.

- A Fauna Management Plan will be prepared and include a requirement for experienced ecologists to conduct pre-clearance surveys and experienced fauna spotters/catchers to be onsite during any clearing.

- Fauna crossings and fauna-friendly fencing will maintain fauna movements through the site. Details about site fencing and fauna crossings will be available as part of the Project submission to the DCCEEW under the EPBC Act. Boundary fencing will be designed with input from adjacent neighbours.

- The key ecological elements of the site’s landscape, including riparian corridors, will be retained and enhanced during construction and operation.

PEP has completed a comprehensive desktop assessment and three ecological field surveys of the proposed Project area. This included targeted waterway assessments to confirm aquatic habitat values and targeted surveys for Matters of National Environmental Significance (MNES), including the White-throated Snapping Turtle and the Australian Lungfish.

The surveys showed the Project’s waterways are ephemeral and provided limited habitat for MNES aquatic fauna. The waterways within the study area were found to often be turbid and stagnant due to current land uses in the catchment with no permanent flow in the waterways.

While no MNES species were found during these investigations, mitigation measures will be included in the final design to minimise any potential downstream impacts on the White-throated Snapping Turtle and the Australian Lungfish and their habitats.

These control measures will include:

- limiting ground disturbance on the site during construction and operations

- certified erosion and sediment control specialists preparing Preliminary Erosion and Sediment Control Plans (ESCP), which are available on the GRC Development Applications website www.gladstone.qld. gov.au/development-application-tracking and Project websites www.miriamvalesolarfarm.com.au/project-documents and www.miriamvalebess.com.au/project-documents.

WEEDS AND PESTS:

PEP is committed to meeting and upholding responsible land management practices. A Weed and Pest Management Plan (WPMP) is being developed for the Project’s construction and operation phases. A weed survey conducted in September 2024 assessed for priority weed species such as Giant Rats Tail (GRT) grass, Parthenium and Feral Leucaena. No Parthenium was identified during these surveys. PEP acknowledges GRT is a considerable issue throughout the site and within the broader region, including along road corridors to the site.

A weed-control program targeting GRT will commence on the site prior to construction, with regular weed control and surveys during the Project’s operational phase. PEP will also require all vehicles and machinery entering the Project site to be cleaned and certified by an authorised weed and seed inspector, and cleaned down prior to leaving.

FIRE EMERGENCY AND BUSHFIRE RESPONS

We are committed to assessing and advising the community regarding any potential risks or impacts associated with fire or emergencies on the site and ensuring these are mitigated and managed.

PEP engaged fire and emergency response specialist Halliwell to develop an Emergency Response Plan (ERP). This plan will be implemented prior to construction and will inform Project design, as well as manage fire risks during construction and operation.

The ERP will include:

- Risk assessment – identifying risks related to the solar and battery technology being used, particularly any release of harmful smoke or fumes in an emergency and how these may disperse or be managed in plant design and operations.

- Emergency response procedures – steps to isolate the affected area, alert emergency services, and evacuate personnel from onsite and surrounds. There are currently no planned changes to existing exit roads adjacent to the Project.

- Public communication protocols – guidelines for alerting the surrounding community including the roles of the Project, Rural Fire Service (RFS), and the Queensland Fire Department (QFD).

- First responder training – ensuring emergency services are aware of the risks posed by site incidents and are appropriately trained to respond.

- Personal Protective Equipment (PPE) – providing first responders and personnel with suitable PPE for chemical exposure.

- Health and safety training – regular drills and safety training for staff working onsite.

- Coordination with local authorities – collaboration with the RFS, QFD, emergency services and health and safety authorities to ensure a rapid and coordinated response, including any additional resources for emergency response or additional medical treatment if necessary.

The ERP will be released to key stakeholders for input and feedback in the second quarter of 2025.

Given the inconsistent phone and internet coverage in the surrounding area, it is likely sirens would be sounded, and/or door knocking used, to alert neighbours in a worst-case fire scenario. However, we will work closely with our neighbours to identify the best notification processes based on their needs.

For added preparedness, the QFD and RFS will be notified at least one week prior to the commissioning of any major electrical infrastructure at the facility.

FIRE EMERGENCY RESPONSE:

A fire and emergency response specialist has been engaged to develop an Emergency Response Plan (ERP). This plan will be implemented prior to construction starting and will be used to inform the design of the Project as well as manage fire risks during construction and operations.

The ERP will include:

● Risk Assessment – identifying specific risks related to the solar and battery technology being used,

particularly any release of harmful smoke or fumes in an emergency event and how these may disperse

or are managed in plant design and operations.

● Emergency Response Procedures – steps to isolate the affected area, alert emergency services, and

evacuate personnel from on-site and surrounds. There is currently no planned change to existing exit

roads adjacent to the Project.

● Public Communication Protocols – guidelines for alerting the surrounding community including the

roles of the Project, Rural Fire Service, and the Queensland Fire Department.

● First Responder Training – ensuring emergency services are aware of the risks posed by any site incidents and are appropriately trained to respond.

● Personal Protective Equipment (PPE) – providing first responders and personnel with suitable PPE for

chemical exposure.

● Health and Safety Training – regular drills and safety training for staff working on-site.

● Coordination with local authorities – collaboration with the Rural Fire Brigade, fire departments,

emergency services and health and safety authorities to ensure a rapid and coordinated response,

including any additional resources for emergency response or additional medical treatment if necessary.

The BESS technology and chemistry proposed for the Project is LFP (Lithium, Ferrous and Phosphate). LFP

batteries are inherently safer and less prone to thermal runaway than Lithium Nickel Manganese Cobalt

(LNMC) batteries. LFP batteries shut down if damaged, preventing thermal runaway and ensuring safety

throughout shipping, transit and operation.

PEP is committed to assessing and advising the community regarding any potential risks or impacts associated with fire or emergencies on the site and ensuring these are mitigated and managed.

During construction and operations, PEP will seek to establish a working group with the local Rural Fire Brigade

and neighbours to coordinate and enhance bushfire preparedness for the local area.

PEP engaged a leading Queensland bushfire consultant to prepare a Bushfire Management Plans (BMP) for the Solar Farm and BESS. The BMPs were informed by GRC’s bushfire hazard overlay code, and other guidelines developed across Queensland. New South Wales fire guidelines have been adopted where Queensland guides were not fully defined (i.e. access road design suitable for firefighting).

The purpose of the BMPs is to outline the design of the sites and construction, and the operational activities required to protect the Solar Farm and BESS from bushfire impacts.

The BMPs are available on the GRC Development Applications website www.gladstone.qld.gov.au/ development-application-tracking and the Project websites www.miriamvalesolarfarm.com.au/project- documents and www.miriamvalebess.com.au/project-documents. The include details on fire breaks and access tracks, buffer areas, ongoing vegetation and weed control programs and fire water tanks.

A final bushfire and firefighting plan will be developed in consultation with the local RFS and QFD prior to construction.

PEP is committed to working with our neighbours and the community to manage bushfire risks and events and will establish a working group with the local RFS and neighbours to coordinate and enhance bushfire preparedness for the local area. We have spoken with local RFD members regarding firefighting resources and are open to subsidising equipment upgrades if the need arises.

Staff will undertake emergency training, and a chain of command will be established to effectively manage incidents. Routine fire drills will be conducted, along with safe work procedures that include emergency management and PPE requirements.

FLOOD, STORMWATER, EROSION AND SEDIMENT

During Project design, specialist flood modelling of the site was completed for 1-in-100 (1%) and 1-in-200 (0.5%) Annual Exceedance Probability rain events, and the assessment maps the overland flow and water depth. As the Project does not materially change the existing overland conditions, natural storm and flood waters will continue to flow across the site as they do now, both during construction and throughout operations.

Project Flood Assessment and Stormwater Management Plans have been completed and are available on the GRC Development Applications website www.gladstone.qld.gov.au/development-application-tracking and the Project websites www.miriamvalesolarfarm.com.au/project-documents and www.miriamvalebess.com. au/project-documents.

In accordance with Australian Standards, equipment that contains oil (such as power transformers) will be enclosed in a retaining wall (bunded) to capture the unlikely release of oil or oily water from these units. These bunding systems will be pumped out occasionally and the contents transported offsite for safe disposal or reuse.

Just like household construction materials, BESS equipment is designed to prevent the release of any chemicals used in their manufacture, during normal operating conditions. PEP will receive and adhere to Safety Data Sheets once BESS equipment is selected.

Sediment control plans and measures will be put in place where necessary to ensure construction soils, stockpiles and other site materials used during operation will not wash off-site when it rains.

DECOMMISSIONING:

PEP will develop a Decommissioning Management Plan to minimise environmental impacts and ensure the land is returned to an agreed state at the end of the Project. Many of the components can be recycled, while non-recyclable materials will be safely removed from site and disposed of in accordance with regulations. PEP will work with GRC to fulfil all decommissioning requirements.

About the Miriam Vale Solar Farm

PEP is proposing the use of a modern, high-quality solar tracker system that incorporates the latest module technologies to maximise exposure to sunlight. These systems adjust the orientation of solar panels to follow the sun’s path to maximise energy absorption. These systems are designed for efficient, low-cost installation and enhanced energy production.

Studies on operational solar farms have demonstrated PV panels are designed to reflect minimal light and absorb as much energy as possible. The equipment is designed to minimise reflection and glare and maximise energy output.

The proposed Miriam Vale Solar Farm nameplate capacity is up to 500 megawatts, with the potential to generate about 1,200 gigawatt-hours per year of renewable energy from the Solar Farm into the NEM annually. This energy is equivalent to the energy use of about 200,000 Queensland homes annually.

The movement of the solar panel trackers, on which groups of solar panels are mounted, is very slow as they follow the sun throughout the day. Minimal noise is generated by these devices.

All Tier 1 solar modules are coated with an anti-reflective material allowing solar systems to be commonly used in airports, where glare would be dangerous for pilots. For example, Tullamarine Airport in Melbourne has the largest solar installation of any Australian airport, spanning an area nine times the size of the Melbourne Cricket Ground. Brisbane Airport has 22,000 solar panels, Adelaide Airport 5,000, and Mount Isa Airport 820.

This improved manufacturing technique also minimises reflective losses and traps more light, which increases the amount of energy converted. This improves their energy output and lowers costs.

The Fresnel equations are used to measure how light reflects and transmits off surfaces. This method predicts roughly 4% of sunlight is reflected from a solar panel during normal use at a 90° angle. This is similar to light reflecting off dams or lakes, and is about 70% less reflective than white concrete.

The ‘heat island effect’ refers to large-scale solar farms creating localised increases in ambient air temperatures for surrounding areas. The Queensland Government’s Solar Farm Guidelines advise there is limited evidence-based risks around solar farms in Queensland causing a heat island effect. Accordingly, mitigation measures are not currently considered necessary.

Worldwide heat island effect studies of solar farms have produced conflicting results. Several studies that indicated an increase in ambient air temperatures within a solar farm also found the heat generated dissipated rapidly over a short distance. For example, one study found at 30m from a solar PV array, the air temperature variation was indistinguishable from ambient air temperature. Another study found while annual average air temperature at a height of 2.5m increased by up to 1.90C, it dissipated at 5m, and the solar farm cooled completely overnight resulting in minimal external heat or residual heat impacts (Fthenakis and Yu, 2013).

Glossary of Terms

Array Array A collection of solar panels.

BESS Battery Energy Storage System

BMP Bushfire Management Plan

BMS Battery Management System

DCCEEW Department of Climate Change, Energy, the Environment and Water

EPBC Act Environment Protection and Biodiversity Conservation Act 1999

ERP Emergency Response Plan

ESCP Erosion and Sediment Control Plans

Fresnel equations Describes the light reflection and transmission at material boundaries

GRC Gladstone Regional Council

GRT Giant Rats Tail

LFP Lithium, Ferrous and Phosphate

LVIA Landscape and Visual Impact Assessment

MNES Matters of National Environmental Significance

Nameplate Capacity The maximum output a power-generating unit is designed to produce under ideal conditions

NEM National Energy Market

PCCC Trust Port Curtis Coral Coast Trust

PEP Private Energy Partners

PPE Personal Protective Equipment

PV Photovoltaic

QFD Queensland Fire Department

Riparian corridors Vegetation strips along watercourses

RFS Rural Fire Service

RNTBC (PBC) Registered Native Title Body Corporate (Prescribed Body Corporate)

RPEQ Registered Professional Engineer of Queensland

Solar Panel Arrays: A solar panel array is a collection of multiple solar panels connected to capture sunlight and convert it into electricity. The panels are typically arranged in a series or parallel configuration to achieve the desired voltage and current for the system’s electrical needs.

Thermal Runaway: A condition in which an increase in temperature causes a further increase in temperature, often leading to destructive outcomes. In batteries, thermal runaway can occur when excessive heat generation exceeds the battery’s ability to dissipate heat, potentially causing fires or explosions.

TIA Traffic Impact Assessment

WPMP Weed and Pest Management Plan

Helpful websites

GRC Development Applications www.gladstone.qld.gov.au/development-application-tracking Miriam Vale Solar Farm www. miriamvalesolarfarm.com.au/ Queensland Solar Farm Guidelines www.epw.qld.gov.au/ data/assets/pdf_file/0012/16122/solar-farm-guidelines-communities.pdf

About PEP

Private Energy Partners (PEP) is an affiliate enterprise of Quinbrook Infrastructure Partners (Quinbrook). Quinbrook is a global business founded in 2015 by Queenslanders who have invested in more than 200 low carbon, renewable, storage and critical minerals projects over the past 25 years. PEP is Quinbrook’s dedicated development, delivery and operations service provider, specialising in renewable energy projects across Australia, the US and UK.